New engines for energy transition:

alphagamma® Stirling engines from Frauscher Motors

We convert heat into electricity: quietly, cleanly and sustainably!

Company

“In contrast to the material world,

the knowledge potential emerging

from Research & Development

knows no end”

Josef Frauscher

Research

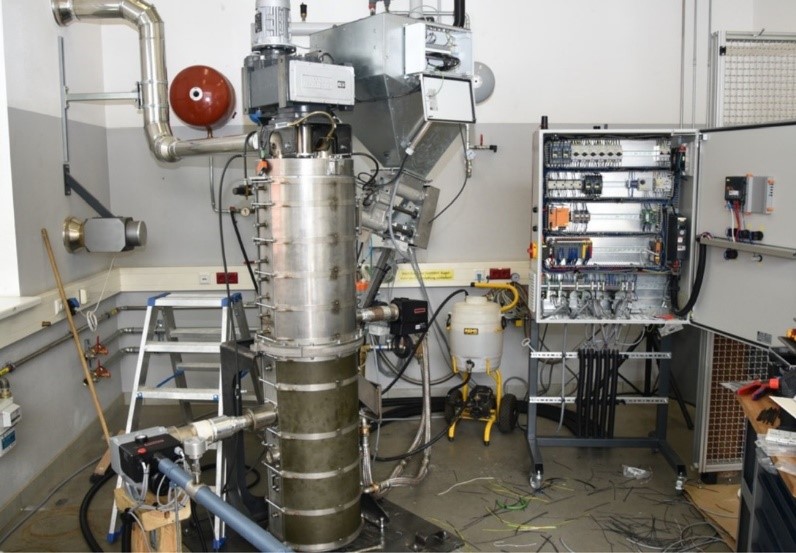

In the course of engine research and development, we were able to take advantage of a range of support from public funds. In addition to decisive help for the construction and equipment of our research centre, it is particularly the thematic programs of several sponsors that made a significant contribution to our success. In representation of this, we would like to invite you to take a closer look at the results of two extremely successful projects: the lean gas CHP and the biomass gasifier burner.

Click on “Prototypes” to get an impression of our research work in the course of prototype development in the period from 2006 to 2017.

New Stirling engine technology

For many years, we focused on improving engines based on the Alpha, Beta, and Gamma principles, achieved only limited success. The main reason for this was the high piston forces in conjunction with lubrication oil-free operation. In the course of solving the problem, the idea arose of reducing the piston forces with the aid of a stepped piston. This resulted in a combination of the alpha process with the gamma process, which is why we chose the term “alphagamma®” process The significant improvements compared to the previous state of the art are not only theoretically demonstrable through thermodynamic calculations but have also been revealed in practical applications after more than 100,000 hours of operational experience.

The novelty of the method has been confirmed by the following patent offices:

- European Unitary Patent EP3622167

- German Patent No. 10 2017 109967

- United States Patent US11,725,607

- Japan 2020-513399 (Decision to Grant)

- Registration in other countries

Products

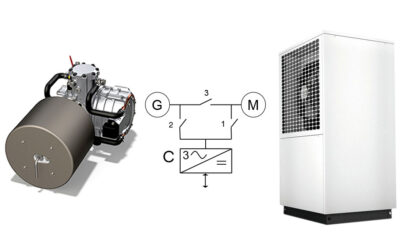

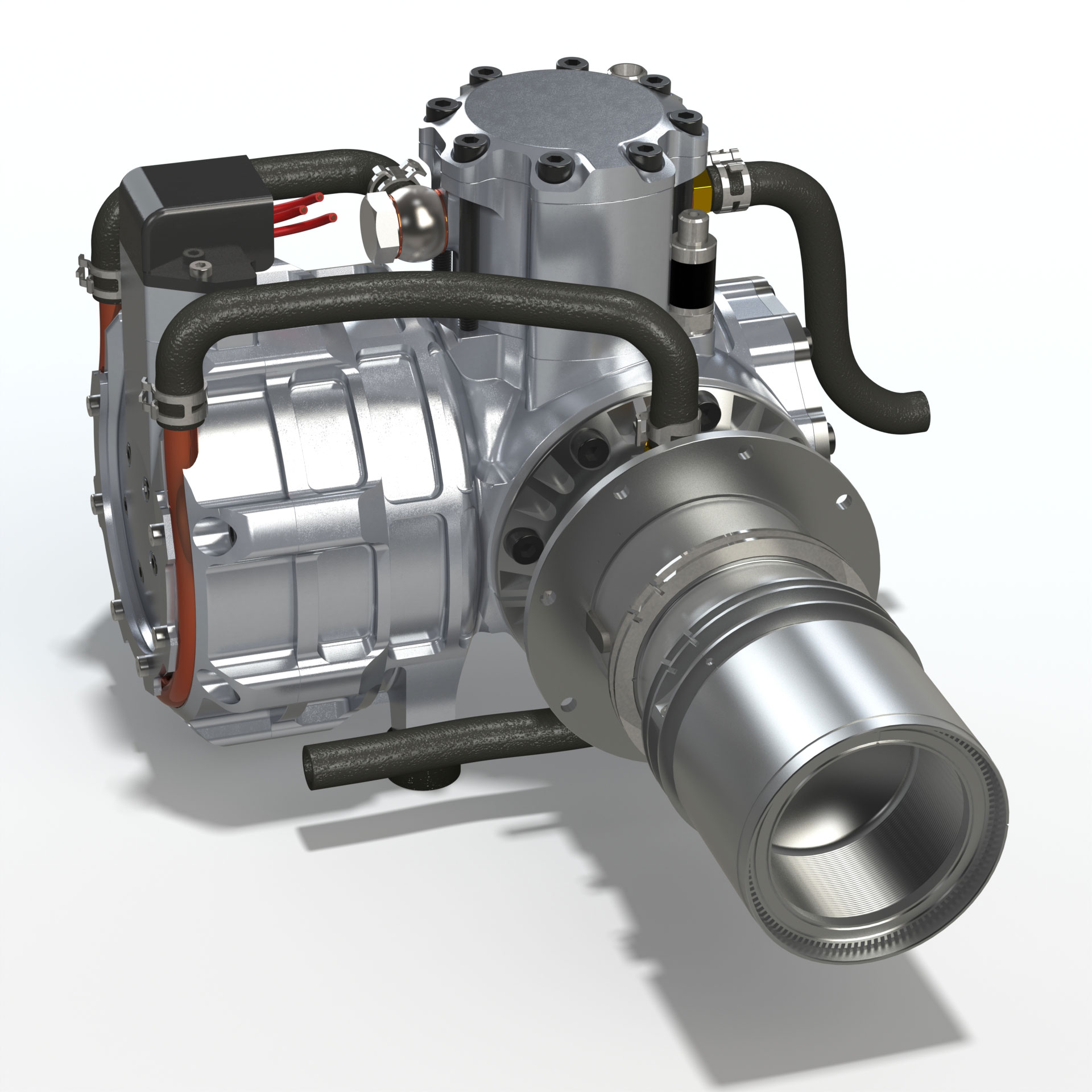

In the course of years of research, we learned how to solve complex requirements in the simplest possible way. Reduced to five moving parts, based on alphagamma® technology, we were able to create a motor concept with an integrated generator with properties that enable new energy-related applications. The following two-engine modules form the core of our product range:

Stirling module Gen70

1.5 kW shaft power, 1.2 kW electrical: Basic module for liquid or gaseous fuels or for external heat supply, for example, for 24/48V battery charging, heating, air conditioning and stand-alone solutions.

Stirling module Gen500

8.3 kW shaft power, 7.5 kW electrical: Grid-connected asynchronous generator 3×400V, prepared for external heat supply or for burner equipment for most combustible gases.News

Experimental Edition Set: also available in 48-volt technology!

In response to requests from numerous micro CHP enthusiasts, we have decided to make the successful Stirling Experimental Edition Set compatible with 48-volt systems. This paves the way for marketable energy solutions in the field of grid independence, backup and...

Stirling Module Gen70D with Radiation Receiver!

For years, we have been asking ourselves what methods we can develop to utilise our customers' various heat sources to generate electrical energy. The use of high-temperature radiation as well as the transfer of heat through heat conduction - often in conjunction with...

Hybrid drive for heat pumps: secured power supply and more

The heat pump is a remarkable machine: it is able to convert the energy input up to 6 times intoheating energy. However, there is a small downside to the otherwise very sophisticated and quiet mode of operation: on the coldest days, its efficiency (COP = coefficient...